A

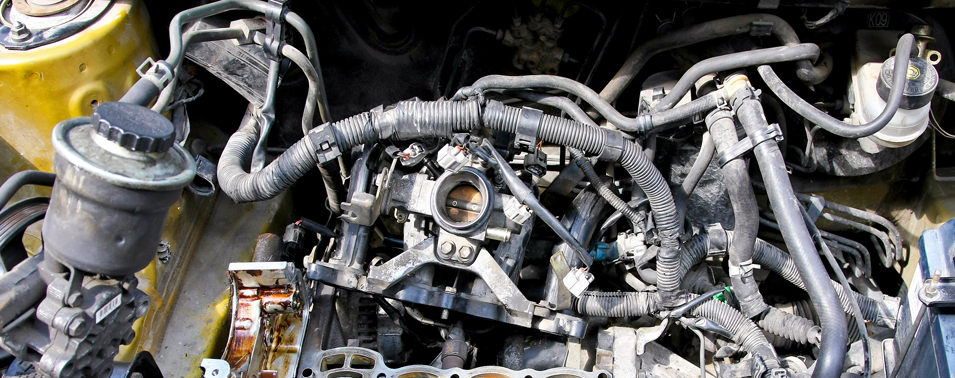

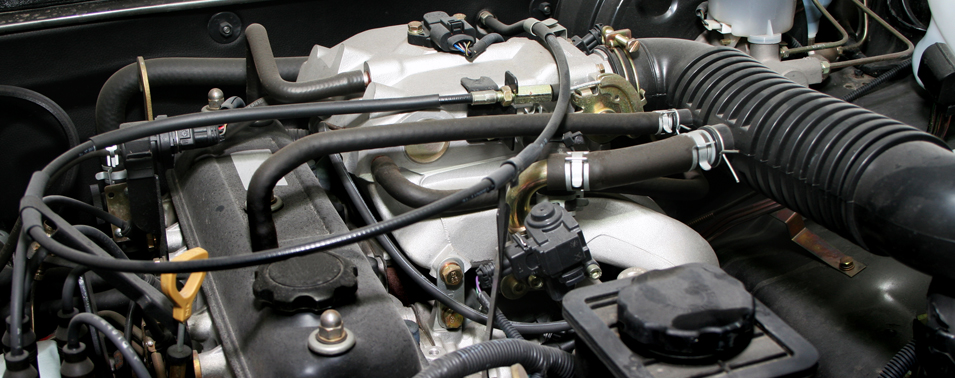

crankshaft grinding can rotate at very high speeds. That’s why a

crankshaft grinding must be perfectly balanced and fine-tuned to transform the maximum linear power of the motor into its rotary equivalent without generating damaging torsions or vibrations. A repaired

crankshaft grinding, just like a brand new crankshaft grinding must possess an effective damper at its opposite end to minimize torsion vibrations often caused along the

crankshaft grinding length by cylinders that are farthest from the output end that tend to act on the torsional elasticity of the metal. All these minute adjustments must be perfect to get a

crankshaft grinding to act as it’s supposed to and behave as perfectly as any EOM crankshaft grinding would.

crankshaft grinding Montreal repair shop RMMOTEUR has all the necessary equipment to make a perfect

crankshaft grinding repair on all motor types, old or new, car or truck, diesel or gas-powered.

Less

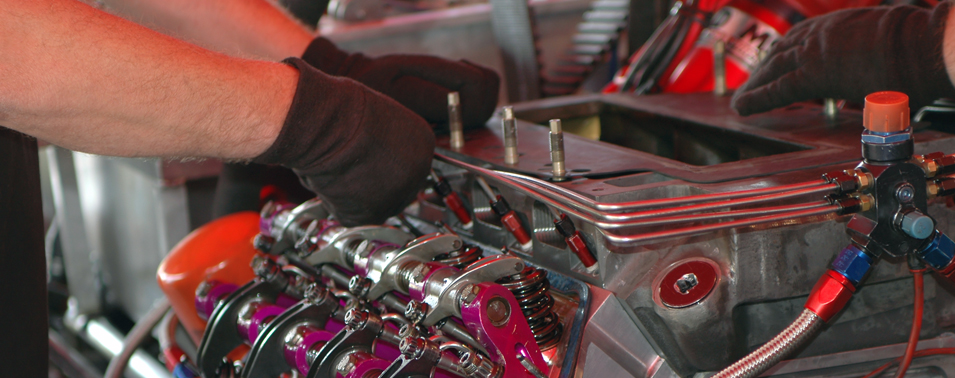

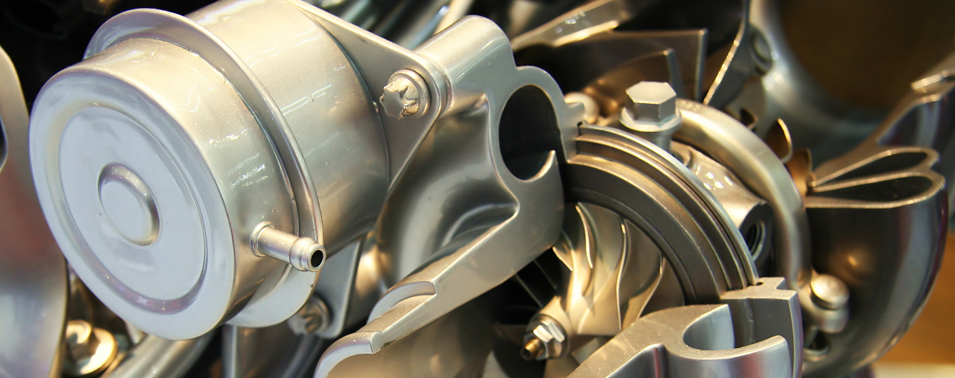

crankshaft grinding repairs are one of the most delicate repair jobs around. Only highly experiences tradesmen can do a good-as-new crankshaft grinding repair job able to withstand long-term, motor-pounding stress. Our crankshaft grinding Montreal repair shop has every piece of machinery and equipment enabling us to repair whatever type of crankshaft grinding that needs to be fixed, on the spot. Our more than 20 years of hands-on motors repairs of all types has allowed us to develop crankshaft grindingexpertise like no other in the greater Montreal region. We deliver the best crankshaft grinding repairs in Montreal, Quebec and guarantee our crankshaft grinding repairs to the fullest. Feel free to call on us for any crankshaft grinding repairs you might need and visit our huge machine shop filled with any motor-repair equipment you might need, making us the most competent and best-equipped crankshaft grinding repair garage around.

Less

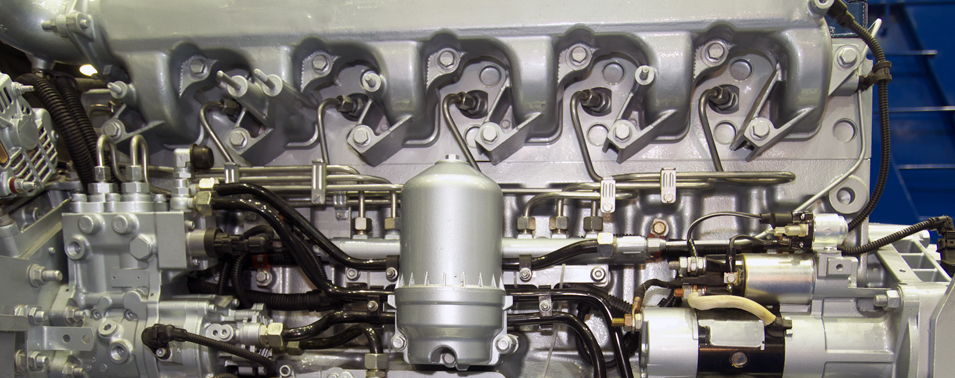

A

crankshaft grinding is found in small and large motors alike having multicylinders. The complex shape of a

crankshaft grinding fits the number of pistons transforming their explosive power into the rotation power needed to get vehicles running with all available power. Individual piston strokes must synch with the

crankshaft grinding design to create an even flow of power transfer from each individual piston to a central force delivery systems represented by the

crankshaft grinding. A

crankshaft grinding will have a central rotation axis from which it can power-up vehicle wheels. As a

crankshaft grinding gets high lateral stress loads from each of the multiple cylinders composing an engine, this

crankshaft grinding must also be supported by added bearings besides the one found on each end of the

crankshaft grinding.

Less

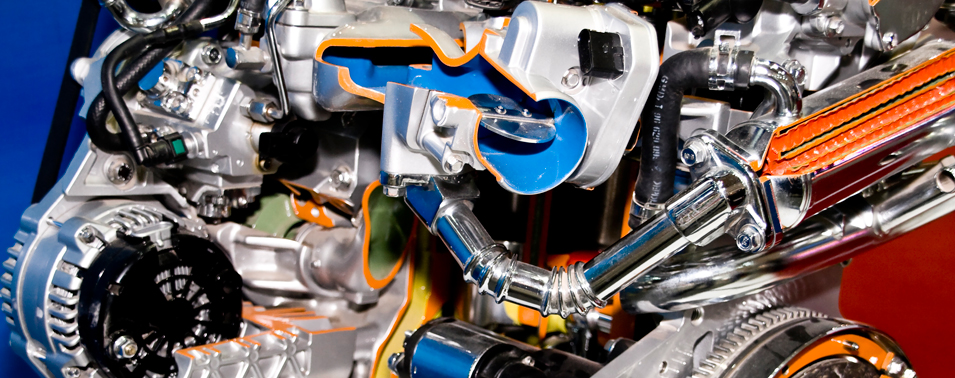

Each motor type, make and manufacturer designs each

crankshaft grinding to optimize fuel efficiency, minimize heat production and coordinate all motor parts into a single, perfectly-integrated power delivery system. This perfect power unit must be considered as a whole when repairing a

crankshaft grinding to get back to the original specifications the original

crankshaft grinding maker determined. To do just that, every

crankshaft grinding repair, adjustment or refitting must recreate original parameters to recover the engine’s full capacity. Fixing a broken

crankshaft grinding is much cheaper than buying a new motor, so making the right choice for

crankshaft grinding repairs is paramount in not only fixing your broken

crankshaft grinding, but in saving money as well.

Less